University of Kansas Central Utility Plant Powers Unique Learning Opportunities

Adjacent to the University of Kansas Integrated Science Building (ISB) is KU’s new Central Utility Plant (CUP), which produces hot and chilled water for the KU’s Central District, which includes the ISB, a new Burge Union and two residence halls. The $15 million CUP was designed to provide utilities and educational opportunities for student research and includes a classroom — complete with windows looking into the machine room — for faculty and students to work closely with industry partners and provide opportunities for outreach with other universities and educators.

Foundation Distinguished Professor of Chemical & Petroleum Engineering Mark Shiflett is working to elevate the research and educational opportunities of this space, while reducing KU’s carbon footprint and creating stronger ties with industry.

“Our proposal is to provide a location for companies to test bench-scale to pilot-scale CO2 capture and conversion technologies using ‘real’ flue gas in a modern power plant designed for research and education.”

“The facility will provide the opportunity for faculty, graduate, and undergraduate students at KU to study alongside industry scientists exploring how to reduce the impact of CO2 on our environment. The University of Kansas would be the first university to install CO2 systems in their own power plant for research, education and reducing carbon footprint.”

Shiflett’s vision includes retrofitting one of the chillers with a new low-global warming refrigerant so students can study the cooling capacity, energy efficiency and emission differences while working alongside industry scientists from the refrigerant and chiller manufacturer.

The enhanced learning environment Shiflett proposes also includes benefits to students beyond those studying engineering or other hard sciences.

“Humanities students will also be exposed to authentic research to understand how public policies intersect with technological innovation and the challenges to implementation.”

Prof. Shiflett is working with industry partners to retrofit the chiller this Fall and is in discussions with Oil & Gas companies about piloting CO2 capture and conversion technologies.

Foundation Distinguished Professor (2016-Present)

University of Kansas

Department of Chemical and Petroleum Engineering

ME Capstone Project: KU Central Utility Plant Chiller Retrofit

The new central utility plant (CUP) at the University of Kansas has two 900 ton York chillers that will provide chilled water for cooling the new Integrated Science Building (ISB), Kansas Student Union and Central District. The chillers will initially operate using refrigerant R-134a (1,1,1,2-tetrafluoroethane). A mechanical engineering Capstone project led by Cade Albert, Chad Sevart, Michel Alhathal, Josh Seybert and Yong Hahn (shown standing in front of the chillers) and supervised by Prof. Mark Shiflett (Chemical Engineering) and Prof. Tom DeAgostino (Mechanical Engineering) are measuring the cooling capacity and energy efficiency of R-134a to determine the baseline chiller performance. Plans are to retrofit one of the chillers to a new lower global warming refrigerant in the Fall of 2018 to measure the differences in cooling capacity and energy efficiency relative to the R-134a baseline measurements.

New Thermodynamics Experiment for Undergraduate Chemical Engineering Lab

Dr. David Griffin, Prof. Mark Shiflett, Mr. George Whitmyre

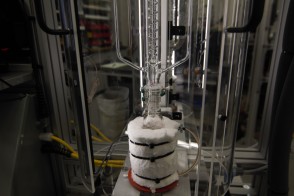

A new thermodynamics experiment was designed and constructed for the Fall, 2017 undergraduate Chemical Engineering Laboratory, C&PE 616. Designing a VLE-based separation process requires information about the compositions of phases (vapor and liquid) as a function of temperature, pressure, and overall composition. The objective of this experiment is to obtain data so that the students can predict the isobaric vapor-liquid equilibrium for a particular ternary mixture by measuring the VLE in the constituent binary mixtures. The students learn to operate four modified Swietoslawski ebulliometers which operate at ambient pressure for measuring the boiling temperature for pure component and mixtures to calculate activity coefficients near the limits of infinite dilution.

The infinite dilution activity coefficients, obtained by data regression, will be used in common activity coefficient models (NRTL, Wilson, Margules) to predict the activity coefficients over the whole concentration range, and then for the construction of binary phase diagrams. The predictive capabilities of the Regular Solution activity coefficient models will be tested for the binary systems and compared with known literature values. Based on these results, the students choose the best model for the prediction of the ternary VLE phase behavior. Results from the isobaric experiment allow construction of useful x-y and T-x-y phase diagrams and solving a design problem which requires an isothermal or adiabatic flash calculation. Students are also introduced to ASPEN Plus (version 10) process simulation software to perform flash calculations. For a discussion of VLE phase diagrams, see S. I. Sandler, Chemical, Biochemical and Engineering Thermodynamics, 5th Ed., J. Wiley and Sons, 2017.

C&PE 626 Chemical Engineering Laboratory II (Spring 2017)

C&PE 616 Chemical Engineering Laboratory I (Fall 2016)

Senior Lab, kinetics

ASPEN Plus® Tutorials

Taught ASPEN Plus® modeling using video presentations at the University of Kansas and University of Delaware. Video library includes: Hydrogenation of Benzene to Cyclohexane (KU), Hydrogenation of Benzene to Cyclohexane, Solids modeling, and Reactor modeling.

C&PE 661 Undergraduate Honors Research

Advise undergraduates in chemical engineering thermodynamic and reaction engineering experiments with my graduate and post-doctoral researchers

C&PE 651 Undergraduate Research

Advise undergraduates in chemical engineering thermodynamic and reaction engineering experiments with my graduate and post-doctoral researchers

Adjunct Professor (2011-2016)

University of Delaware

Department of Chemical and Biomolecular Engineering

CHEG 345 Chemical Engineering Laboratory I

Junior Lab, kinetics and vapor-liquid equilibria theory and experimentation, and safety

CHEG 445 Chemical Engineering Laboratory II

Senior Lab, distillation theory, operation of pilot-scale column, and process hazards analysis

CHEG 473/474 Junior/Senior undergraduate research

Advised 39 students during the past six years to: design new kinetics experiment for Junior lab, reactivate heat-exchanger experiment for Junior lab, upgrade pilot-scale distillation column from batch to continuous operation for Senior lab, create ASPEN tutorial videos for introductory course in ChE, measure friction and wear properties for bioderived and synthetic lubricants, and publish manuscripts.

UNIV 401/402 Undergraduate Thesis

Advised undergraduate thesis student, obtained departmental research funding, Project: Friction and Wear Characteristics for Bioderived Lubricants – Advantages versus Synthetic Lubricants.

CHEG 112 Material and Energy Balances

ASPEN modeling

You must be logged in to post a comment.