Designing Molecular Gate Adsorbents for Natural Gas Purification using PSA

The PSA system is used to study the separation of contaminants such as N2, CO2, CO, and H2S from natural gas (NG). Shiflett lab group is currently working with Dr. David Corbin (Senior Scientist, CEBC) to develop new molecular sieves for the kinetic separation of N2, CO2, CO, and H2S from NG.

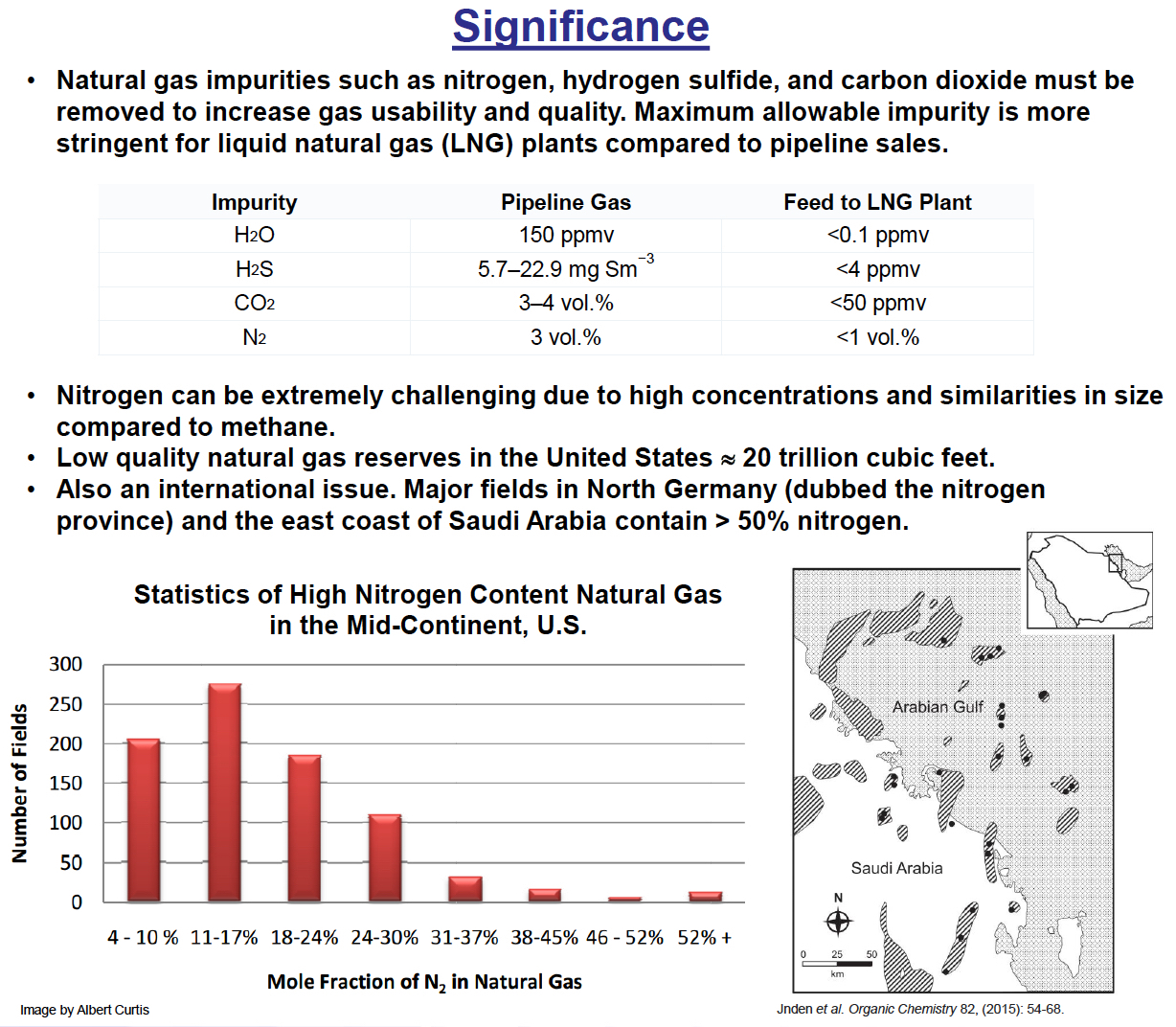

To remove contaminants, the natural gas is fed under pressure through a PSA column containing molecular sieve which can adsorb N2, CO2, CO, and H2S. After the sieve is saturated with N2, CO2, CO, or H2S, the flow is redirected to the next column and the first column is depressurized to desorb the N2, CO2, CO, and H2S and regenerate the sieve. In some cases the desorption is slower than the adsorption step, so multiple columns are needed to allow time for complete column regeneration. Development of a molecular sieve to remove N2, CO2, CO, and H2Sfrom CH4 based on size difference is challenging because they only differ in size by 0.2 Angstroms (N2, CO2, CO, and H2S are about 3.4 to 3.6 Angstroms vs. CH4 is 3.8 Angstroms). However, if a molecular sieve can be developed for this application, it will significantly reduce the cost of separating inert gases such as N2, CO2, CO, and H2S and possibly He from NG. Current technologies, such as cryogenic plants for N2 removal, are complex and have high capital and operating costs compared to using a PSA system. The PSA technology is also field deployable, modular and can be scaled out to meet the capacity of the gas field.

Sulfite Removal from Wine

Within the winemaking industry, sulfites are used as a chemical additive to prevent wines from spoiling or browning as they age, and to ensure that wines are free of unwanted bacteria at the time of opening. While there are obvious advantages to using sulfites in wine, a small percentage of the population experiences severe adverse health effects as a result of a sulfite sensitivity. These people may experience asthma attacks, rashes, and headaches as a results of the presence of sulfite in wine. Our research group is designing a device to go on the end of a wine bottle to remove sulfites from wine at the time of pouring. Students are working to design and print a 3D prototype, while also investigating materials such as zeolites, ion exchange resins, and clays to discover which materials may selectively remove sulfite without changing the taste of wine. Students are using a combination of qualitative and quantitative techniques to investigate which materials may be more successful at removing sulfites than the few commercial products that already exist on the market. It is the hope of our group to design a cost-effective single use device to allow wine drinkers to enjoy wine without the presence of unnecessary chemical additives.

Water Desalination via Gas Hydrate Technology

Global population continues to increase, consequently the demand for freshwater keeps rising. As a response to this pressing need, several desalination plants have developed during the past decades. Most of these utilize reverse osmosis (RO) or multi-stage flash distillation (MSF) as their separation technology. However, pumping large amounts of liquids to elevated pressures and the significant thermal heating requirement makes these technologies expensive. An alternative desalination technology is the use of clathrate hydrates.

A clathrate hydrate is a crystalline cage-like water structure which encloses a guest molecule. The conditions at which clathrate hydrates form are specific to the guest molecule. In past experiments, researchers have investigated several different refrigerants (HCFC-22, HFC-134A, HCFC-141b, etc.) as clathrate formers to separate brine from freshwater and have observed clathrates form at temperatures above the freezing point of water. This is an important benefit because it decreases the energy needed to cool the seawater to reach crystallization conditions. Nonetheless, due to the ozone depletion and global warming potentials related to CFCs, HFCs, and HCFCs, the clathrate formers investigated in the past are no longer environmentally viable.

The purpose of our research is to identify an optimum clathrate former. We will achieve our goal through fundamental studies on phase transition properties, hydrate formation kinetics, and solubility of refrigerants in saline water, while simultaneously sustaining a pragmatic approach to desalinating water by considering heat integration and technology coupling.

You must be logged in to post a comment.